Resources

The vehicle mover knowledge hub

The platform for insights, information, and tips about vehicle moving. Learn best practices, download free templates, e-books, and more to empower your business.

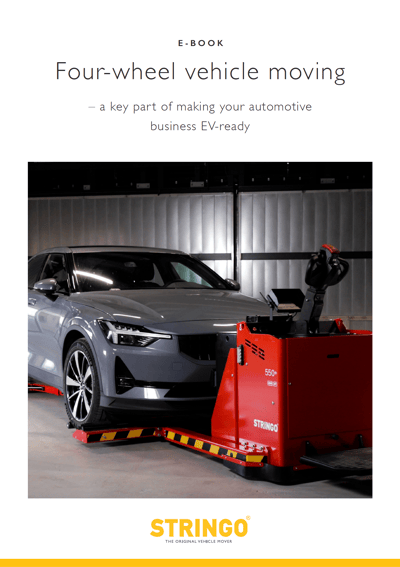

Downloads

Download our free templates, e-books, checklists, and product sheets.

Articles

Get insights, learn best practices and find useful information about vehicle moving.

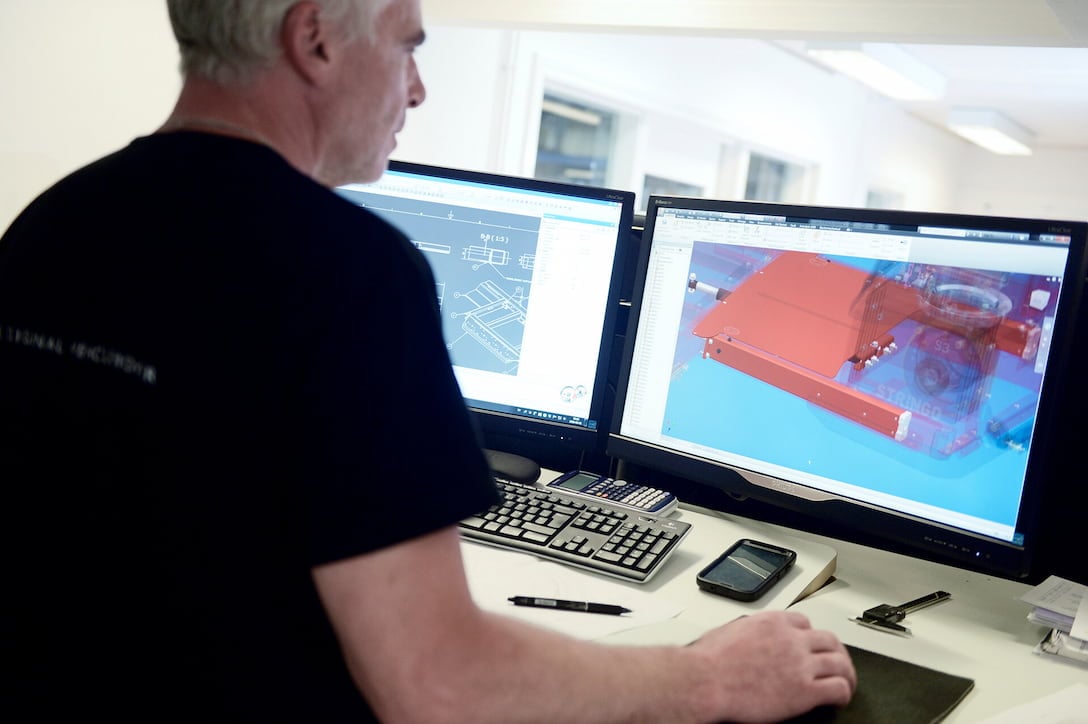

How innovation drives safety in vehicle mover product development

From launching whole new vehicle movers to tweaking existing models—safety is a key driver in ...

Humans of Stringo - Mattias Löfgren

Here’s a guy who likes tinkering with nuts and bolts both on and off work. But assembler Mattias ...

3 challenges when moving cars in police custody (and how to solve them)

Working in the police force, what are the main challenges when moving and storing vehicles that you ...

Join our newsletter

Stay ahead with Vehicle Moving Insights

Don’t miss out on the latest insights, news, and product updates. Subscribe to our newsletter Vehicle Moving Insights.

Videos

Video /

Video /

Detroit Historical Society - What Drives You

Video /

Owls Head Transportation Museum - What Drives You

Case Studies

Tale of a Clay Modeller

We interview Harry Burgess of Aston Martin’s design team to learn first hand the ins and outs of ...

How to move vehicles in tight spaces

When moving vehicles, a commonly used method is to rely on manual pushing by several people as well ...

When challenging environments calls for creative solutions

Heavy cars, a tight space, and a bumpy ramp right in the middle of the assembly line – that's ...

News

Explore upcoming automotive trends and get the latest news about vehicle movers.

News /

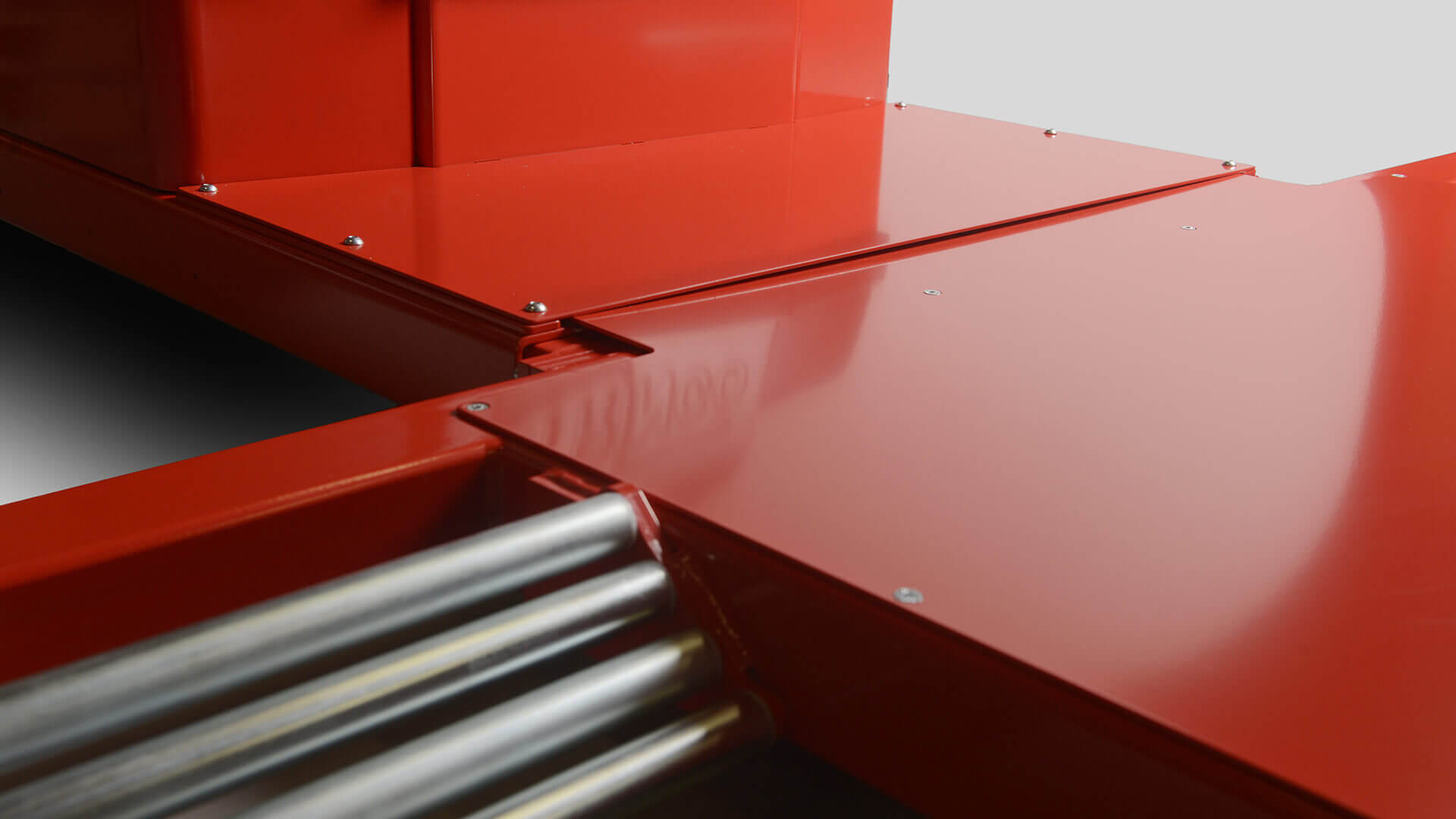

New Stringo S5 Launches, Introduces The Next Generation of Vehicle Movers

2024-02-22. Nyland, Sweden. Stringo, the original and world’s most loved vehicle moving solution, ...

News /

New Management Group Member Christer Östman Adds Production Talent To Stringo

2023-10-20. Nyland, Sweden. Stringo, the original and world’s most loved vehicle moving solution, ...

News /

Stringo Showcases New 4WM At Automotive Testing Expo 2023

2022-10-13. Nyland, Sweden. Stringo, the world’s original and most loved vehicle moving solution, ...